Tool making requires very high technical qualifications and keenness to quality and detail. For one to be able to produce tools of required standards, correct rules and regulations must be followed during the entire process. This is especially so because tools are the greatest essentials in the manufacturing industry and therefore influence the entire operations of the economy.

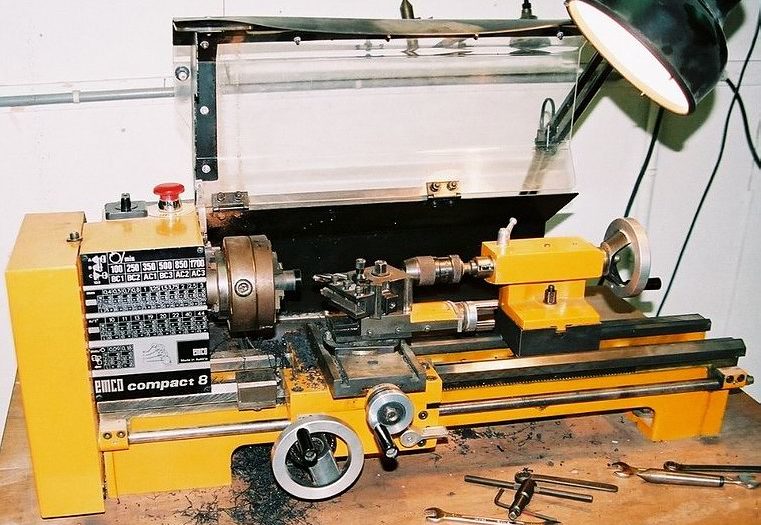

In the olden days, most tools were made by hand. Tool makers had to use tools like polishing machines, grinding machines and files to create a quality finish on their tools. This has however changed with time due to the introduction of numerically controlled milling, boring and grinding machines which make the tool making process easy and fast.

There is a need for a tool maker to be able to understand and interpret technical drawings of an end product which they intend to get. Operation of technical machines such as computers and lathes is a plus for one to be able to produce tools that exhibit quality and modern standards without compromising on the functionality of the tool in question.

Personal Protection

The tool making process requires a tool maker should protect himself from any hazards. One should use protective clothing such as gloves to protect his hands, overalls, hearing devices to protect the ears from the loud noise and eye protectors. One also needs to be technically fit and a self driven person to survive as a tool maker.

It is important for anyone in this industry to embrace modern technologies which evolve by the day. Maintenance of accuracy and competence is the only way through which you can be able to produce quality tools that can compete fairly in the present market. There is a lot of new information about recent developments which you can take advantage of to boost your skills and abilities as a tool maker.

The Importance Of Tool Makers

The manufacturing industry is mainly dependent on tools. Tool makers are therefore very important in ensuring a constant supply of tools for manufactures. Tools are used to make various items in different industries including central heating boilers, pen tops and dashboards manufacturing companies.

Different types of tools are required for making different items. It is therefore essential for one to be able to determine the best materials to use in making tools for particular uses. One should be creative enough to develop new skills and learn how to operate modern machines used in making advanced tools commonly used in the current market.

There is a lot of technicality that tool makers need to exercise to be able to produce good quality tools. This means that one need to be well trained in various aspects such as specific quality of materials needed in the making of particular types of tools.

Qualities Of Required For Tool Making

Whether one is using a machine or hands to make tools, there is need for accuracy and understanding of standard requirements in the making of each tool. One should know how to configure technical data, interpret drawings and assemble parts so as to get the required sizes and shapes of tools. It is only through high standards of accuracy that one can be able to produce the right quality of machines.

There is need for attention to detail and great precision for tool makers to get the best. The tool making work has however become a lot easy with the availability of computer aided designs and computer aided manufactures. Computer numerical control and wire erosion are some of the new technology bits that have made tool making a lot easy. Enthusiasm for learning new skills is therefore very essential for one to be able to make tools of modern standards.